Types of Wood: Guide to Choose the Best Wood for your Office Furniture.

Hey guys! Welcome to another #MondayToShine! I trust you had an amazing weekend with your family and friends! The weekend is over guys and this is another brand new week to be the best version of yourself.

Today on the blog, We will be sharing with you on Guide to Choose the Best Wood for your Office Furniture. Do not forget guys, we always love to hear from you in our comment section below. Now about Guide to Choose the Best Wood for your Office Furniture , read along!

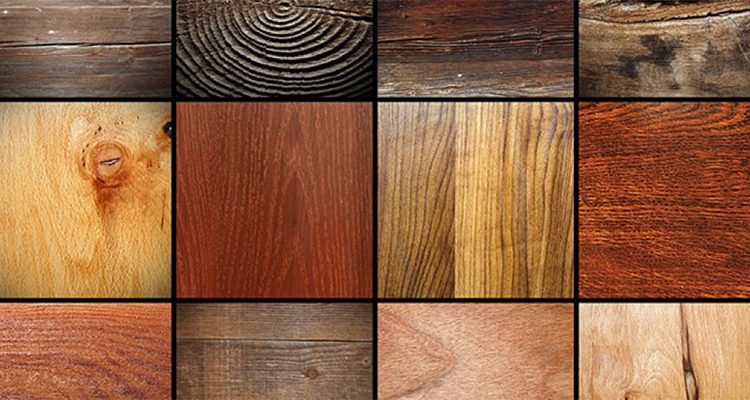

When it comes to furniture, wood is one of the most commonly used materials. Almost any type of wood can be used for this purpose. However, all materials are not created equally; there are a few types of wood that are revered for their durability, beauty, and versatility.

Wood for office furniture is available in a wide range of materials and styles to suit many different tastes as well as budgets. Wood desks, tables and shelving units designed for home offices or commercial spaces are sold in modern as well as traditional looks. Dark, light and every wood finish color in between is available in hardwood or less expensive wood office furniture.

Most wood office furniture falls into the category of either modern or traditional in style. Modern wood office pieces tend to have clean lines without detailed trim. Unlike traditional wood office desks that are rectangular in shape, modern versions may be round, oval or even an irregular free-form design. Both types of office furniture are sold in a variety of colors and materials. In this guide, you will learn about different varieties and characteristics of wood and which of these wood best suit your budget, taste and style.

Types of Wood – 2 major types.

Hardness is one of the simplest ways to distinguish the wood used for furniture. Contrary to the popular belief, hardwood is not necessarily harder and denser compared to softwood. In botanical terms, hardwood comes from flowering trees while softwood comes from conifers. Both hardwood and softwood are used for everything from structural to decorative purposes.

Hardwood

Hardwood comes from Angiosperms such as maple, oak, and walnut. These trees lose their leaves annually. As they grow slowly, hardwood has denser wood fibers (fiber tracheids and libriform fibers).

As hardwood is rare, it is relatively expensive compared to softwood. However, there are exceptions. For example, gum is a hardwood that comes at a price compatible with most types of softwood. Hardwood is durable, comes with close grain, and requires low maintenance. It also comes with low sap content and good fire resistance. Not all types of hardwood are ideal for making furniture.

Softwood

Softwood comes from gymnosperms, which are evergreen trees. Softwood includes trees such as pine, spruce, fir, cedar, juniper, redwood, and yew. Evergreen trees tend to be less dense than deciduous trees. Thus, it is easier to cut them down.

Softwood consists of tracheids and wood rays. As vessels are absent, softwood is also called non-porous wood. It comes with loose grain, higher sap content, and lighter color. However, it comes with poor fire resistance. The fine and lightweight structure makes softwood ideal for making furniture.

Hardwood vs Softwood: The difference

| HARDWOOD | SOFTWOOD |

|---|---|

| Hardwood comes from angiosperm, deciduous trees. | Softwood comes from coniferous, evergreen trees. |

| It comes with rough wood texture. | It comes with fine wood texture. |

| The presence of vessels makes it porous | The absence of vessels makes it non-porous. |

| Tracheid content is around just 5% to 10%. | Tracheid content is around 90% to 95%. |

| The complex anatomical structure makes hardwood denser. | The relatively less complex anatomical structure makes softwood less dense. |

| Not all types of hardwood are ideal for furniture making. Being expensive, they are usually used in high-end furniture manufacturing. | Almost all types of softwood are ideal for furniture making. In fact, about 80% of all timber comes from softwood. |

This comparison chart above is believed to had given the detail differences between the Hardwood and the Softwood.

Hardwoods -Samples

I. Mahogany

Mahogany is one of the most popular hardwood tropical trees. Mahogany wood is prized for its beauty, durability, and color. It is relatively free of voids and pockets. The color darkens over time. As a result, it is a popular choice for furniture.

- Color – Reddish-brown to blood red.

- Density – Medium texture and moderately heavy.

- Grain – Straight.

- Common Uses – High-end furniture, interior millwork, exterior doors, windows, and trim.

- Finishing – Sanding sealer.

II. Walnut

Walnut (black walnut) is one of the most popular woods for furniture in the U.S. The dimensional stability, shock resistance, strength properties, and the rich coloration are the reasons behind its popularity.

- Color – Lighter pale brown to a dark chocolate brown with darker brown streaks. Sapwood is pale yellow-gray to nearly white.

- Density – Medium texture, fairly lightweight.

- Grain – Moderately open grain.

- Common Uses – High-end furniture, carving, flooring accents, musical instruments, and gun stocks.

- Finishing – Should be finished with oil-based polyurethane

III. Red Oak

Oak trees are native to the northern hemisphere. There are around 600 species of oak, both deciduous and evergreen. Oakwood is remarkably strong, heavy, and durable. It is also resistant to fungal attacks.

- Color – Pinkish red to blonde

- Density – Very hard and strong.

- Grain – Varied and openly porous grain patterns.

- Common Uses – Furniture, cabinets, molding, trim, flooring, paneling, turning.

- Finishing – Natural finish or oil, but they may vary.

IV. Ash

Ash trees are medium to large trees that grow in most parts of the world. Ashwood feels smooth to the touch. It is durable, tough, and flexible. It has excellent nailing, screw holding, and gluing properties. Hence, carpenters love to work with ash wood. However, it produces a distinct and moderately unpleasant smell while working on it.

- Color – Light, creamy-brown.

- Density – Tough, flexible.

- Grain – Open-grained with occasional brown streaks.

- Common Uses – Flooring, millwork, boxes/crates, baseball bats, and other turned objects such as tool handles.

- Finishing – Takes all finishes.

V. Birch

Birch trees are widespread in the Northern Hemisphere. Though it is closely related to Oakwood, it is much harder. Birch plywood is probably the most widely used as it is hard, stable, affordable, and readily available.

- Color – Heartwood is light reddish brown with nearly white sapwood.

- Density – Hard, medium weight.

- Grain – Usually straight or slightly wavy with small pores.

- Common Uses – Plywood, boxes, crates, turned objects, cabinets, seating, millwork, furniture, interior doors.

- Finishing – Takes all finishes.

VI. Maple

Maple trees are mostly native to Asia. But they are also found in Europe, North Africa, and North America. The maple wood is sturdy, resistant to splitting, and durable. It can be wiped clean with a damp cloth, making it ideal for kitchen furniture.

- Color – The heartwood is typically a darker shade of reddish brown. Sapwood color ranges from nearly white to an off-white cream color. But it can be reddish or golden hue.

- Density – Moderately hard but strong.

- Grain – Closed and generally straight, but may be wavy.

- Common Uses – Everything from furniture and woodenware to flooring and millwork.

- Finishing – Takes all finishes.

VII. Cherry

Cherry wood comes from the cherry fruit tree. Cherry wood has rich color, smooth grain, and flexibility, making it a popular choice for furniture manufacturers. It also steams easily, making it ideal for use in curved designs.

- Color – The color is light pinkish brown when freshly cut. It darkens to a medium reddish brown over time.

- Density – Stiff, strong, medium weight, and moderately hard.

- Grain – Closed and straight.

- Common Uses – Cabinetry, fine furniture, flooring, interior millwork, veneer, musical instruments, paneling, turned objects, and small specialty wood items.

- Finishing – Light to natural finishes are recommended.

VIII. Beech

Beech trees are deciduous and native to temperate Europe, Asia, and North America. Beechwood is quite durable and resistant to abrasion and shock. Because beech steam-bends as readily as ash, carpenters love to work with this wood. It also provides an elegant and dated look to furniture. However, it is not dishwasher safe.

- Color – Pink to reddish brown heartwood, sapwood is creamy to pink.

- Density – Very hard and heavy.

- Grain – Straight with a fine to medium uniform texture.

- Common Uses – Chair legs and backs, crates/pallets, railroad ties, flooring, food containers, toys, musical instruments, and woodenware.

- Finishing – Takes all finishes.

IX. Teak

Teaks are tropical hardwood trees native to India, Myanmar (Burma), and Thailand. Teakwood is one of the hardest and most durable of all natural woods. It is resistant to rotting, sunlight, rain, frost, and snow, making it suitable for outdoor construction and furniture. However, it is expensive and sometimes hard to find.

- Color – Heartwood is golden or medium brown and darkens with age.

- Density – It is heavy and strong.

- Grain – Grain is straight. Occasionally, it can be wavy or interlocked.

- Common Uses – Boatbuilding, veneer, furniture, exterior construction, carving, and turnings.

- Finishing – Finishes best with wood lacquer.

X. East Indian Rosewood

The rosewood trees grow in tropical environments including countries such as Brazil, India, and Madagascar. Rosewood is durable when dried properly. It comes with white chalky deposits that may dull tools and present problems with finishing. However, it is one of the toughest woods.

- Color – Heartwood can vary from golden brown to deep purplish brown, with darker brown streaks.

- Density – Hard, heavy and strong.

- Grain – Usually narrowly interlocked.

- Common Uses – High-end furniture, musical instruments, veneer, and turned wood objects.

- Finishing – Finishes well, but requires initial seal coats.

Softwoods

I. Parana Pine

Parana pine trees also called Brazilian pine are native to southern Americas, especially Brazil. Parana pine wood is free from resin ducts, pitch pockets, and pitch streaks. It has a higher shear strength and nail holding capacity compared to other softwoods. However, it tends to warp and distort during drying and compression.

- Color – Heartwood is light to medium brown, usually with red streaks. Sapwood is yellow.

- Density – Light but hard.

- Grain – Straight, uniform.

- Common Uses – Framing lumber, interior woodwork, sashes, and door stock, furniture case goods, and veneer.

- Finishing – Finishes well, but requires initial seal coats.

II. Eastern White Pine

Eastern white pine trees are widely available in eastern North America. It is one of the most valuable timber species. Eastern pine wood turns golden yellow when exposed to sunlight over time. Once dried properly, it becomes relatively stable. However, it is fairly porous. Thus, it will cup if it absorbs excessive moisture. It is relatively cheap and readily available.

- Color – Heartwood is a light brown with a slightly reddish hue. Sapwood is a pale yellow to nearly white.

- Density – Soft and very lightweight.

- Grain – Straight and tight. However, winter wood and summer wood show a significant difference.

- Common Uses – Exterior millwork, furniture, moldings, paneling, carvings, turning, pattern making.

- Finishing – Finishes well, but must be sealed with water-based or oil-based polyurethane.

III. Lodgepole Pine

Lodgepole pine trees are commonly found in western North America and Canada. The trees can live to be over three hundred years old. However, they seldom do as they are susceptible to bark beetle attacks. The tangential surface of lumber shows a multitude of dimples, especially when stained. It is, therefore, a favorite for paneling.

- Color – Heartwood is light reddish to yellowish brown and sapwood is yellowish white.

- Density – It is moderately strong and lightweight. But heavier than eastern white pine.

- Grain – Straight

- Common Uses – Ideal for construction lumber, plywood, and paneling. It is also used to make doors, windows and furniture, railway ties, mine props, and fence posts.

- Finishing – Finishes well, but must be sealed with water-based or oil-based polyurethane.

IV. Pitch pine

Pitch pine trees are also native to eastern North America. They can grow 50 to 60 feet in height with a trunk of 1-3 feet in diameter. The wood is resistant to fire and abrasion. The high resin content also makes it resistant to decay.

- Color – Heartwood is reddish brown, sapwood is yellowish white.

- Density – Soft and lightweight.

- Grain – Straight grained.

- Common Uses – Heavy construction, plywood, wood pulp, shipbuilding, fences, railroad ties, and veneers.

- Finishing – Finishes well, but must be sealed with water-based or oil-based polyurethane.

V. Scots pine

Scots pine trees are native to northern Europe and Asia. The trees are susceptible to red band needle blight. Scots pine timber is one of the strongest softwoods available. The wood is also resinous. It is less durable, but not susceptible to lyctid borer.

- Color – Heartwood is light reddish brown. Sapwood ranges from pale yellow to nearly white.

- Density – Reasonably strong and lightweight.

- Grain – Straight grained.

- Common Uses – Construction, paneling, boxes/crates, poles, flooring, and interior joinery.

- Finishing – Finishes well, but must be sealed with water-based or oil-based polyurethane.

VI. White Spruce

All the species of spruce trees are native to northern temperate and boreal (taiga) regions. They are also widely distributed throughout the mountain ranges in continental Europe. White spruce wood turns, planes, and molds nicely. It has excellent nailing and screwing abilities. However, it is only slightly resistant to decay.

- Color – Heartwood is creamy white to light yellow or to red-brown. It is not distinct from sapwood.

- Density – Moderately hard.

- Grain – Fine and consistently straight.

- Common Uses – Pulpwood, construction lumber, joinery, millwork, and crates.

- Finishing – Finishes nicely, but when using a sanding sealer, gel stain or toner is recommended.

VII. Red Cedar

Red cedar is a common name for various varieties of cedars growing in the eastern United States region. The red cedar wood (also known as aromatic red cedar) is remarkably resistant to both decay and insect attack. It is highly aromatic and planes and shapes easily. However, it only has moderate screw and nail holding properties.

- Color – Heartwood tends to be red or violet-brown. Sapwood is pale yellow or whitish.

- Density – Hard texture and lightweight.

- Grain – Straight grain with many knots.

- Common Uses – Fence posts, closet and chest linings, carvings, outdoor furniture, birdhouses, pencils, closet interiors, bows, and small wooden specialty items.

- Finishing – Finishes well, but oil finishes are recommended.

VIII. Fir

Fir trees are located throughout most of the North and Central America, Europe, Asia, and North Africa. They usually grow in the mountains. It comes with low shrinkage and reasonable stability. It is also strong and elastic.

- Color – Sapwood is yellowish to reddish-white. Fresh heartwood can be yellowish-brown to reddish-yellow in color. However, it darkens quickly to a brown-red to dark-red.

- Density – Medium-weight and fairly hard.

- Grain – Straight and plain, sometimes wavy.

- Common Uses – Veneer, plywood, and construction lumber.

- Finishing – Finishes nicely. However, you need to take into account the fairly high sap content, which may require a coat of paint.

IX. Larch

Larch trees are native to the cooler temperate northern hemisphere. Larch wood is moderate-to-poorly resistant to fungal attack. However, it is durable and very resistant to rot and pests due to the presence of natural resins. Although knots are common, they are usually small.

- Color – Heartwood is yellow to medium reddish brown. Sapwood is almost white.

- Density – Very good strength and medium weight.

- Grain – Straight or spiraled with an oily texture.

- Common Uses – Veneer, utility poles, fence posts, flooring, boatbuilding, exterior and interior joinery, and construction lumber.

- Finishing – Should be sealed before finishing to prevent bleed-through.

X. Western Hemlock

Western Hemlock species are native to the west coast of North America, growing in the coastal rainforests of Alaska and British Columbia. The wood has an excellent strength-to-weight ratio. It can turn, plane, and shape smoothly. It has a moderate nail and screw holding ability. It also has a reputation for termite resistance. However, outdoor uses require good finishing for avoiding quick decay.

- Color – Heartwood is light reddish brown. Sapwood is slightly lighter in color.

- Density – Soft and light.

- Grain – Straight, with a coarse and uneven texture.

- Common Uses – Boxes, pallets, crates, plywood, framing, cabinets, joinery, and millwork.

- Finishing – Responds best to clear finishes.

XI. Yew (European Yew)

Yew is native to western, central, and southern Europe. The heartwood of the yew tree is very tough and durable. The best timber, however, comes from trees growing in mountainous areas. It is also highly elastic. Thus, it can readily bend, spring back, and remain durable. It is also resistant to most insect attacks.

- Color – Heartwood is orangish brown to darker brown or purplish hue. Sapwood is usually a thin band of pale yellow or tan color.

- Density – Soft, flexible, and moderately heavy.

- Grain – Straight, with a fine uniform texture.

- Common Uses – Bows (archery), veneer, cabinet making, furniture, carvings, and musical instruments.

- Finishing – Finishes well, but must be sealed with water-based or oil-based polyurethane.